COILED SPRING PINS

Coiled spring pins ISO8751, ISO8748, ISO8750

Coiled spring pins are normally available in 3 standards, which are:

ISO8751 light duty (special, upon request)

ISO8750 / DIN 7343 medium duty

ISO8748 / DIN 7344 heavy duty

There are quite significant differences between the three standards/duties and these are being considered during the design and choice of the proper pin. Feel free to ask us and discuss with us your application in order to determine the right solution. There are also special variations of these pins that can have different shape, size, material etc.

Coiled spring pins brings a lot of benefits to your application, for example in comparison to slotted pin ISO8752 or to machined solid pins. The main advantages are:

- Equal stress distribution, no weak point

- Absorb shocks and vibrations, protect host material

- Larger holes tolerances reduce cost for the hole preparation (can be used in drilled or casted holes)

- Swaged chamfers help the installation and also helps to overcome some hole misalignment

- Reusable - allow to assemble and disassemble the pins without hole damage

- Closer diameter tolerances, better contact with the hole

- Are symethrical and have no interlocking, so can be used for automatic installation

Most typical materials are:

- steel C67S with hardness HV 420-545

- austenitic stainless steel 302 (1.4310) or 304 (1.4301) without hardening

We will gladly review your application and help with the choice of the most suitable pin for your assembly. After review of all details and requirements we recommend the best technical and economical solution and we can also assist you with the installation and assembly process. The installation itself is as equally important as the actual fastener choice, and the right assembly process will secure the intergrity, quality and cost efficiency of the final product.

Contact us to discuss your application and to get free consultancy for your assembly.

In the tables below you can see the main dimensions of the all duties/standards. The pins are usually produced with the following ration of diameter to the length:

- shortest pin: 1:2

- longest pin: 1:15

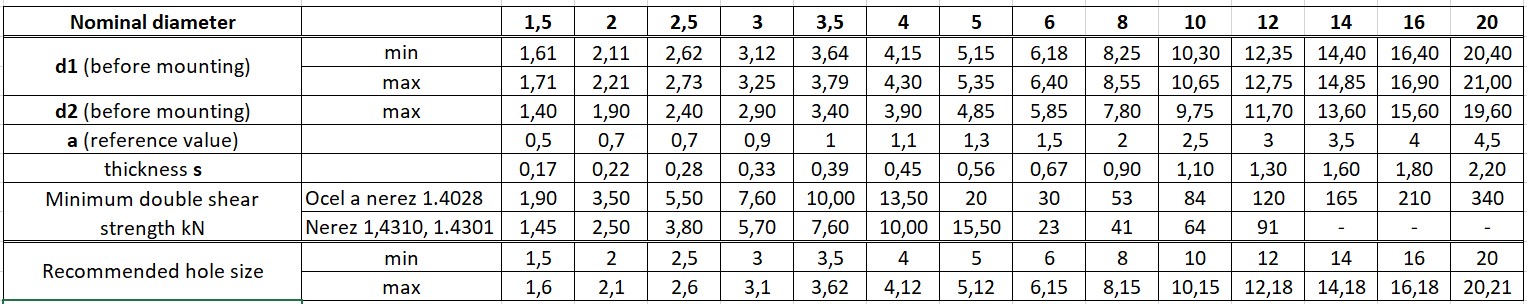

ISO8751 - light duty (mm):

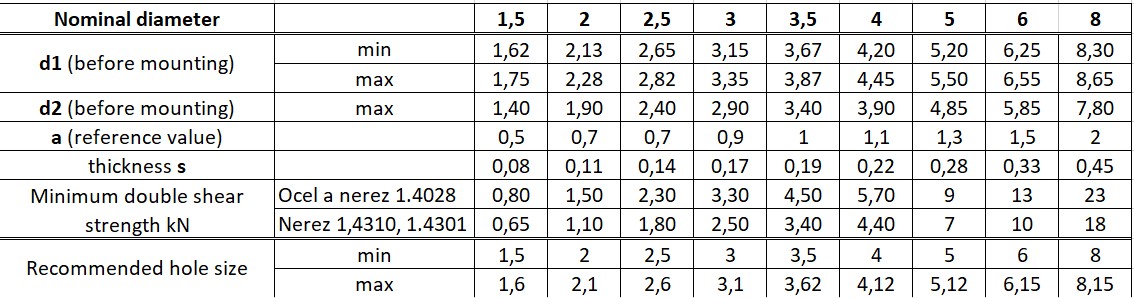

ISO8750 - medium duty (mm):

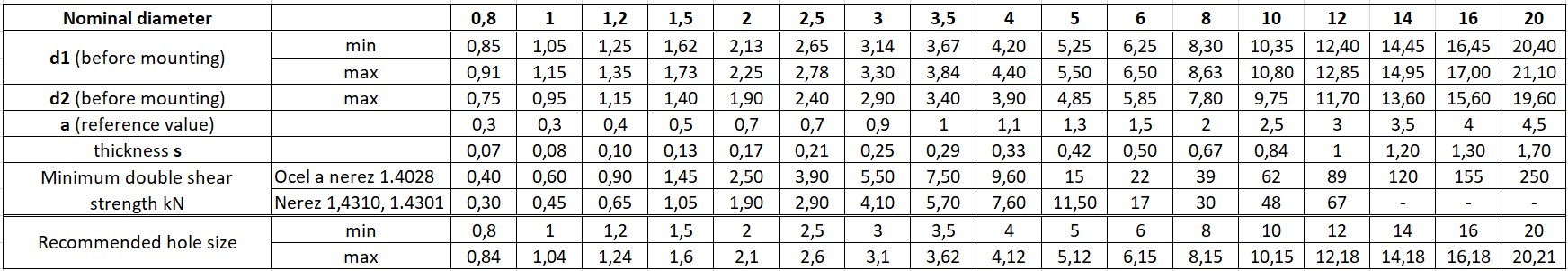

ISO8748 - heavy duty (mm):